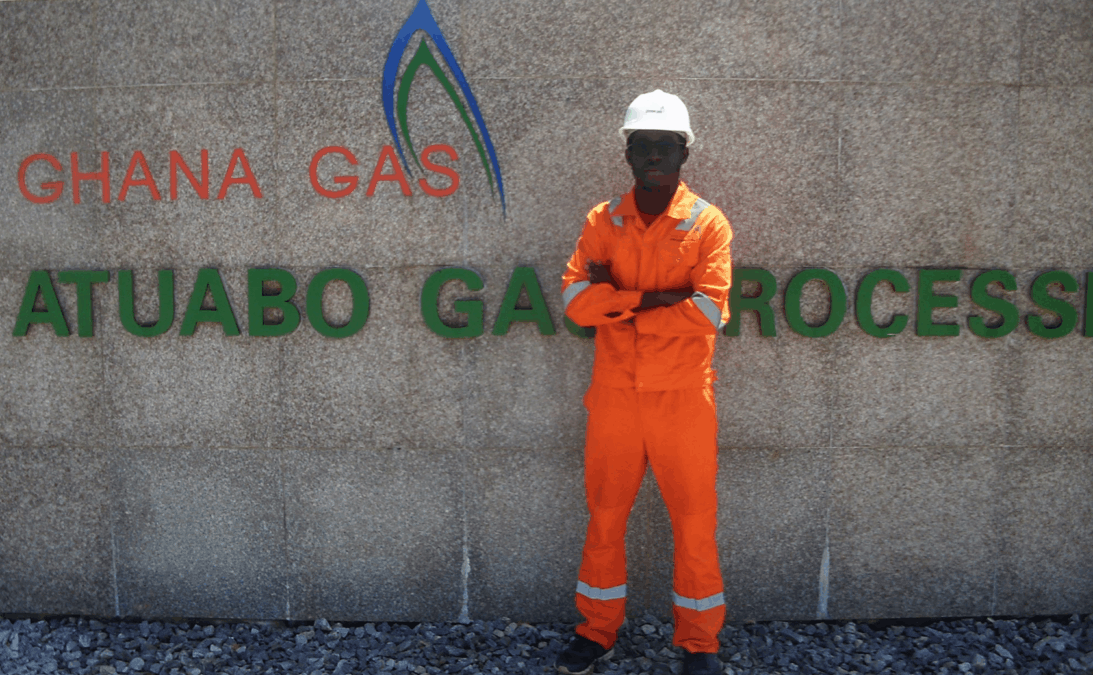

KOBI OCRAN — Close to the coast of the Gulf of Guinea lies one of Ghana’s economic infrastructure masterpieces: the Atuabo Gas Processing Plant, a natural gas processing facility operated by Ghana National Gas Company Limited (Ghana Gas).

Ghana Gas is a Ghanaian state-owned enterprise with the mandate of supplying gas nationwide. It was established in 2010 by the government of Ghana with the goal to expand Ghana’s energy sector. Indeed, Ghana Gas has made and continues to make substantial contributions to the oil and gas industry in West Africa. These contributions are made possible by the hardworking men and women of Ghana Gas who work toward its mission: to be a trusted and reliable gas services company.

In the summer of 2018, I had the opportunity to contribute to Ghana Gas’ mission as an Engineering and Maintenance Intern. My role required that I understand the operations of the plant and assist with maintenance activities.

My first maintenance task took place at the plant’s source well. The source well is the gas processing plant’s (GPP) groundwater supply which is used for a variety of purposes including water for use in the canteen, washrooms, etc. and for the Dissolved Air Flotation (DAF) unit in GPP’s utility sector. The maintenance team and I observed a great deal of corrosion at the source well’s components. We dismantled butterfly valves, applied grease to soften their turning mechanism and drained the rainwater that seeped through it.

My hands-on experience at the plant continued with another exciting maintenance task at the Liquified Petroleum Gas (LPG) tanks. I had the opportunity to run errands by delivering pipes that were used for nitrogen transfer. This was part of a set of procedures termed “hot works”. The University of Arizona Risk Management Services defines “hot works” as any form of operation that deals with portable gas.

To provide a basic overview of my job at the Engineering and Maintenance Department of the plant, I would say it was mostly involved with dismantling and greasing all sorts of components as well as running errands. My tasks were extended to other units of the GPP such as the glycol pump area and the oily water treatment section.

As a data analytics major, I was the only intern who was not pursuing an engineering or petrochemical-related degree. This meant there was a lot for me to learn about processes in a gas plant. Ghana Gas held a series of presentations and safety training sessions to teach and inform interns and new staff about its processes and safety regulation practices. Safety is paramount at Ghana Gas.

It never occurred to me that there exists a vast amount of data generated out of gas plants operations until I came across a few websites that described the role of data analytics in gas processing plants.

Data analytics could very well be the solution to the challenges that exist in gas processing plants. One major problem that often-frustrated engineers at Ghana Gas was rusting, a dilemma apparent in many other gas processing plants around the world. With the help of advanced Supervisory Control and Data Acquisition (SCADA), data analytics can help oil and gas companies make decisions that will mitigate cases of corrosion and speed up their operations, ultimately making them more profitable and environmentally friendly.

On its website, McKinsey Oil & Gas explains that companies in the industry no longer recognize data analytics as just some other option but rather a necessity. The company reported how a team of data scientists incorporated machine learning methods and three years worth of data to mitigate high gas pressure and high oil in water content in an offshore platform in the North Sea. The result: a 1-2% increase and 0.25 to 0.5% increase in production. Although, these figures may seem insignificant the company indicates that “advanced analytics can yield as high as 30 – 50 times investment within a few months of implementation.”

During my internship, I decided to hold a couple interviews and sat with Kamil Seidu, Ghana Gas’ senior engineer for automation and Simon Arthur, the network engineer. They both agreed that data analytics could be of significance to Ghana Gas’ operations. They mentioned the use of SCADA which “runs the IT infrastructure and optical communication network of the plant”. With Ghana Gas’ SCADA systems, the data collected could be used to make predictions and perhaps help analysts build models to mitigate bottlenecks in its operations.

Aside from being involved in the engineering and maintenance department, the Human Resource Department gave me the opportunity to use the skills I gained from my introductory data analytics course to apply the benefits in using the R programming software to track and analyze attendance. From the analysis, I made recommendations to the company to revise its roster planning.

The internship experience at Ghana Gas was truly one of a kind and I am most grateful to the staff of Ghana Gas in making this experience remarkable. My sincere thanks go to the management of Ghana Gas for granting me this unique opportunity. It is without a doubt that it is bound to be a major player in Africa’s oil and gas industry and I am very excited to see what the future holds for Ghana National Gas Company Limited.

John Acquaye

That’s so wonderful